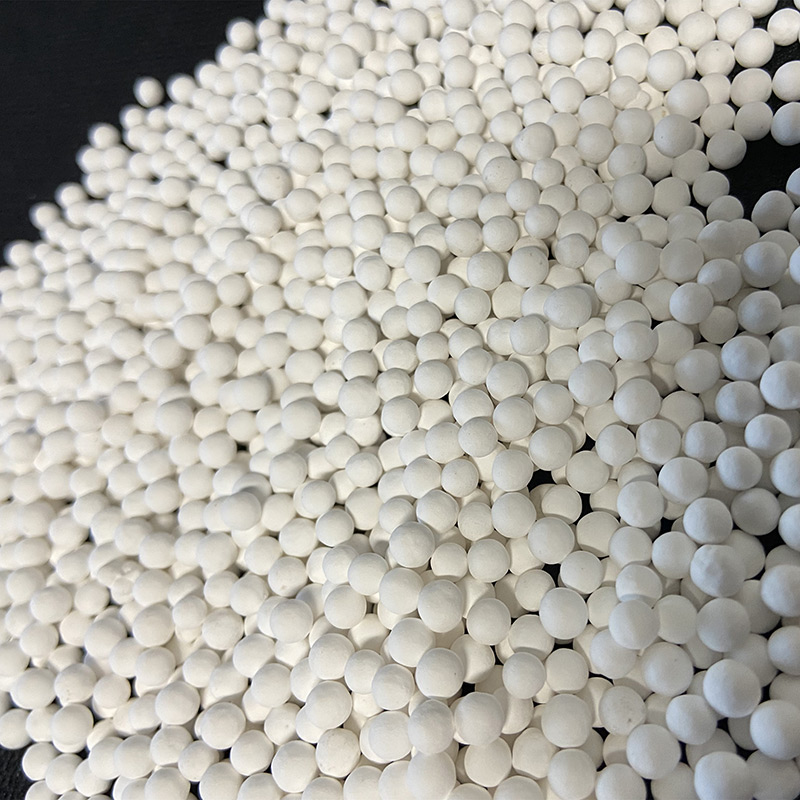

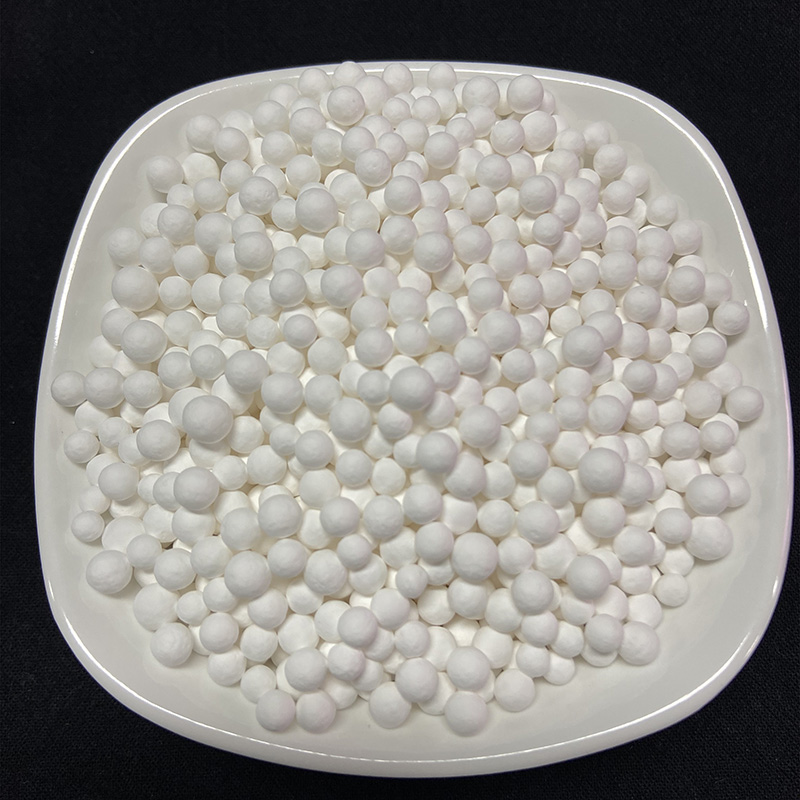

Factory Low Price Aluminum Oxide Ceramic Balls – Alumina Ceramic Filler High Alumina Inert Ball/99% alumina ceramic ball – AoGe

Factory Low Price Aluminum Oxide Ceramic Balls – Alumina Ceramic Filler High Alumina Inert Ball/99% alumina ceramic ball – AoGe Detail:

Physical And Chemical Properties Of Inert Ceramic Balls

|

Physical and chemical properties of inert ceramic balls |

|||||||

|

Element |

Al2O3 % |

60 |

70 |

80 |

90 |

95 |

99 |

|

Fe2O3 % |

≤0.9 |

≤0.8 |

≤0.6 |

≤0.4 |

≤0.3 |

≤0.1 |

|

| The remaining components can be determined through negotiation between the supplier and the buyer when necessary. | |||||||

|

water absorption,% |

3±1,It can also be determined by negotiation between the supplier and the buyer | ||||||

|

proportion,kg/m³ |

2.5-3.0 |

2.7-3.2 |

2.9-3.2 |

≥3.1 |

≥3.2 |

≥3.4 |

|

|

Bulk density,kg/m³ |

1400-1550 |

1400-1650 |

1500-1800 |

1700-1950 |

1800-1950 |

≥1900 |

|

|

Dust, crack or break |

A single bag is less than 5% |

||||||

|

Size deviation |

Uniform sphere, the ratio of the largest to smallest diameter of a ceramic sphere does not exceed 1.2 |

||||||

|

Dimensional tolerance |

≤10mm |

±1.0 |

|||||

|

11—25mm |

±1.5 |

||||||

|

26—50mm |

±2.0 |

||||||

|

≥50mm |

±3.0 |

||||||

|

Free fall strength |

Lossless rate ≥99% |

||||||

|

Compressive strength |

φ3 |

≥250 |

≥300 |

≥350 |

≥400 |

≥500 |

≥500 |

|

φ6 |

≥800 |

≥1000 |

≥1000 |

≥1200 |

≥1500 |

≥1500 |

|

|

φ8 |

≥1500 |

≥1600 |

≥1800 |

≥2000 |

≥2500 |

≥2500 |

|

|

φ10 |

≥2000 |

≥2500 |

≥2800 |

≥3000 |

≥3500 |

≥3500 |

|

|

φ13 |

≥3000 |

≥3000 |

≥3500 |

≥4000 |

≥5000 |

≥5000 |

|

|

φ16 |

≥3500 |

≥4000 |

≥4500 |

≥5000 |

≥6000 |

≥7000 |

|

|

φ20 |

≥6000 |

≥6000 |

≥7000 |

≥8000 |

≥10000 |

≥12000 |

|

|

φ25 |

≥7000 |

≥7000 |

≥8000 |

≥10000 |

≥15000 |

≥17000 |

|

|

φ30 |

≥8000 |

≥9000 |

≥10000 |

≥12000 |

≥17000 |

≥19000 |

|

|

φ38 |

≥10000 |

≥12000 |

≥13000 |

≥15000 |

≥20000 |

≥22000 |

|

|

φ50 |

≥12000 |

≥14000 |

≥16000 |

≥18000 |

≥22000 |

≥26000 |

|

|

φ75 |

≥16000 |

≥18000 |

≥20000 |

≥22000 |

≥25000 |

≥30000 |

|

|

50-75 |

55-75 |

60-80 |

≥80 |

≥82 |

≥85 |

||

|

Wear rate % |

≤2 |

≤1 |

|||||

|

acid solubility,% |

≤6 |

||||||

|

Alkalinity,% |

≥77 |

≥85 |

≥90 |

≥92 |

≥95 |

≥97 |

|

|

Refractoriness,℃ |

≥400 |

≥500 |

≥700 |

≥1000 |

≥1000 |

≥1000 |

|

|

Resistant to sudden pressure difference |

Non-destructive rate ≥ 99%, no change in compressive strength and pressure after sudden change is less than 25% |

||||||

|

Resistant to sudden temperature changes |

Lossless rate≥99% |

||||||

|

Package |

Iron drum packaging |

Packed in iron drums, sealed with thick PP or PE plastic bags |

|||||

| Woven bag packaging |

Available in sturdy and UV-resistant woven bags |

||||||

| Note: Bulk density data is for reference only, not as a basis for acceptance. | |||||||

Another Note: See Table 5 For The Water Absorption Of 99 Filler Balls

|

99 Filling Ball Water Absorption |

||

|

99 filler |

diameter |

diameter |

|

roll forming |

φ<25mm |

<5% |

|

Machine press forming |

φ>25mm |

<10% |

99.5% Technical Indicators

|

Al2O3 |

≥99% |

|

SiO2 |

≤0.14% |

|

Fe2O3 |

≤0.04% |

|

CaO +MgO |

≤0.03% |

|

TiO2 |

≤0.06% |

|

Na2O |

≤0.1% |

|

K2O |

≤0.1% |

Physical Index Of Chemical Filler Ball

|

CONDITION |

INDEX |

|

load softening (yb/t370-1995) |

Deformation under 0.2mpa pressure is less than 0.6% |

|

Thermal shock resistance (yb/t376.2-1995) |

1200°C down to 600°C. 10 times without surface cracks |

|

Reburn line changes (gb/t3997.1-1998) |

1400 ℃ for 12 hours, the maximum value is 0.25%, the average value is less than 0.20% |

|

Bulk density (gb/t2997-2000) |

3.2-3.50 g/cm3 |

|

crushing strength |

Meet more than 230 kg/cm2 |

|

Apparent porosity |

12-18% |

|

Bulk density |

2.1-2.3g/cm3 |

Chemical Packing Ball Packing

1)Ordinary packing: polyethylene woven bag with net weight of 25kg, plus pallet

2)Steel drum packaging: 100L steel drum packaging, pallets can be added

Product detail pictures:

Related Product Guide:

We follow our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create much more worth for our buyers with our abundant resources, highly developed machinery, experienced workers and great providers for Factory Low Price Aluminum Oxide Ceramic Balls – Alumina Ceramic Filler High Alumina Inert Ball/99% alumina ceramic ball – AoGe , The product will supply to all over the world, such as: Mecca, Peru, Swansea, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. "Your satisfaction is our happiness".

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!