CATALYSTS

-

Ultra-High-Purity Alumina

**Ultra-High-Purity Alumina (UHPA) Overview**

Produced via precision alkoxide hydrolysis, our UHPA achieves 99.9%-99.999% purity with exceptional thermal stability (≤1600°C), mechanical strength, and chemical inertness.**Key Features**

- **Atomic Purity**: Sub-ppm impurity control

- **Customizable**: Adjustable particle size (50nm-10μm) & porosity

- **Multi-Functional**: Superior sintering density, optical transparency (>99%), and corrosion resistance**Core Applications**

◼ **Advanced Manufacturing**:

• Synthetic sapphire growth (LED/display substrates)

• Precision polishing for semiconductors & optics

• High-performance ceramics (IC packaging, solid oxide fuel cells)◼ **Energy Tech**:

• Lithium battery coatings & separators

• Transparent armor & laser components◼ **Industrial Solutions**:

• Petrochemical catalyst supports

• Rare-earth phosphor precursors

• High-temperature furnace parts**Formats**: Nanoscale powders, granules, suspensions

**Quality**: ISO 9001-certified production, batch consistencyIdeal for industries demanding zero-defect materials, UHPA enables breakthroughs in optics, energy, and advanced ceramics with unmatched purity and performance stability.

-

High-Purity Gamma Alumina

High-Purity Gamma Alumina

Produced via advanced alkoxide hydrolysis, this gamma-phase alumina offers ultra-high purity (99.9%-99.99%) with exceptional properties:- High Surface Area (150-400 m²/g) & Controlled Porosity

- Thermal Stability (up to 1000°C) & Mechanical Strength

- Superior Adsorption & Catalytic Activity

Applications:

✔️ Catalysts/Carriers: Petroleum refining, emission control, chemical synthesis

✔️ Adsorbents: Gas purification, chromatography, moisture removal

✔️ Custom Forms: Powder, spheres, pellets, honeycombsKey Advantages:

- Phase purity (>98% γ-phase)

- Adjustable acidity & pore structure

- Batch consistency & scalable production

Ideal for high-performance industrial processes requiring stability, reactivity, and efficiency.

-

AGO-0X5L Catalyst for PA Production from 0-xylene

Chemical Coposition

V-Tl metal oxide coated on inert carrier

Physical Properties

Catalyst Shape

Regular hollow ring

Catalyst Size

7.0*7.0*3.7±0.1mm

Bulk Density

1.07±0.5kg/L

Number of Layer

5

Performance Parameters

Oxidation Yield

113-115wt% after first year

112-114wt% after second year

110-112wt% after third year

Hot Spot Temperature

400-440℃(Normal)

Catalyst Pressure Drop

0.20-0.25 Bar(G)

Catalyst Lifetime

>3 years

Commercial Plant Use Condition

Air Flow

4. 0NCM/tube/h

O-xylene load

320g/tube/h (Normal)

400g/tube/h(Max)

0-xylene concentration

80g/NCM (Normal)

100g/NCM (Max)

Salt Temperature

350-375℃

(According to client plant condition)

Product Features and Services AGO-0X5L, the number of catalyst layers is 5 layers, which is developed and optimized based on the advanced phthalic an hydride catalyst technology in Europe. This type of catalyst has the characteristics of high activity and high yield, and the product quality is stable and reliable. At present, the catalyst research and development and trial production have been completed, and industria production will be carried out soon.

Provide catalyst loading and start-up technical services.

Product History 2013————————————–R&D started and succeed

At the beginning of 2023—————-R&D restarted, confirmation completed

At the middle of 2023——————–Industrial trial production

At the end of 2023———————–Ready for delivery

-

AOG-MAC01 fixed-bed benzene Oxidation to Maleic Anhydride catalyst

AOG-MAC01 fixed-bed benzene Oxidation to Maleic Anhydride catalyst

Product Description:

AOG-MAC01 fixed-bed benzene Oxidation to Maleic Anhydride catalyst taking

Mixed oxide in the inert carrier,V2O5 and MoO3as active components,is used

In fixed-bed benzene oxidation to maleic anhydride. The catalyst possesses the

Characteristics of high activity,high intensity,98%-99% conversion rate,good

selectivity and upto 90%-95% yield. The catalyst has been treated with pre-activation

and processing longlife,the started induction period is reduced significantly,

The service life of the product is up to two years or more.

Physical and chemical properties:items

index

Appearance

Black-blue color

Bulk density,g/ml

0.75-0.81g/ml

Shape specification,mm

Regular hollow ring 7 * 4 * 4

Surface area, ㎡/g

>0.1

Chemical composition

V2O5, MoO3 and additives

Crushing strength

Axial10kg/partical, radial5kg/partical

Reference operating conditions:

Temperature,℃

Initial stage 430-460℃,normal400-430℃

Space velocity,h -1

2000-2500

Benzene concentration

42g-48g /m³good effect, 52g/ /m³can be used

Level of activity

Benzene conversion rate 98%-99%

1. Using oil-benzene is best to the catalyst,because thiophene and total sulfur in benzene will lower the catalyst activity of operating,after the device is running normally,superfine coking benzene can be used.

2. In the process, the hot-spot temperature should not exceed 460℃.

3. The catalyst’s space velocity within 2000-2500 h -1 has the best effect.of course,if the space velocity is larger than this,it also works well,since it is the catalyst with high space velocity.

Package and transportation:

During the storage and transportation process, the catalyst is absolute moisture proof,waterproof and it should not exceed 3 months when it is placed in the air. We can flexibly package according to the customers’requires. -

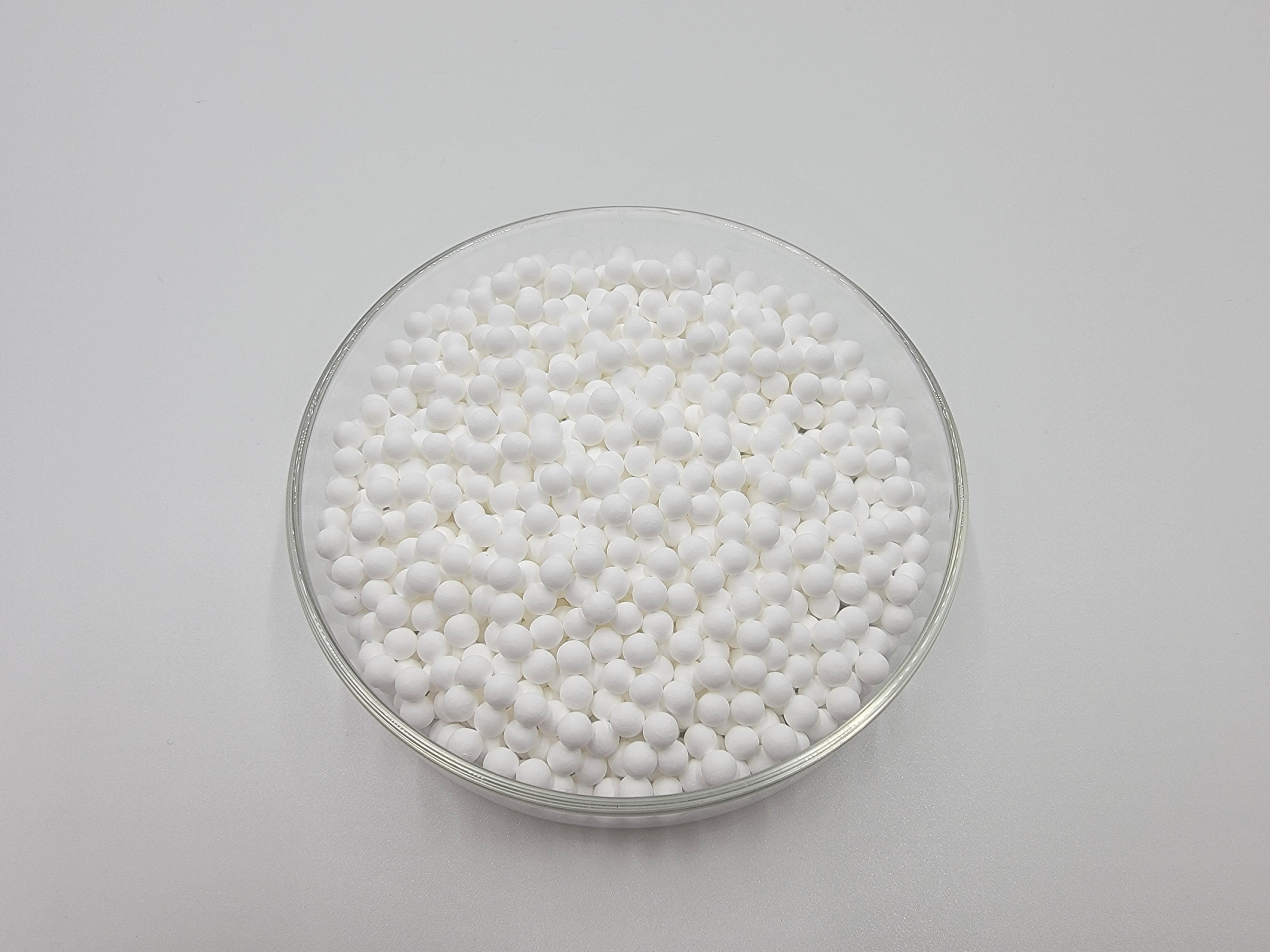

Gamma activated alumina/Gamma Alumina Catalyst Carriers/gamma alumina bead

Item

Unit

Result

Alumina Phase

Gamma Alumina

Particle Size Distribution

D50

μm

88.71

<20μm

%

0.64

<40μm

%

9.14

>150μm

%

15.82

Chemical Composition

Al2O3

%

99.0

SiO2

%

0.014

Na2O

%

0.007

Fe2O3

%

0.011

Physical Performance

BET

m²/g

196.04

Pore Volume

Ml/g

0.388

Average Pore Size

nm

7.92

Bulk Density

g/ml

0.688

Alumina has been found to exist at least 8 form, they are α- Al2O3, θ-Al2O3, γ- Al2O3, δ- Al2O3, η- Al2O3, χ- Al2O3, κ- Al2O3 and ρ- Al2O3, their respective macroscopic structure properties are also different. Gamma activated alumina is a cubic close packed crystal, insoluble in water, but soluble in acid and alkali. Gamma activated alumina is weak acidic support, has a high melting point 2050 ℃, alumina gel in hydrate form can be made into the oxide with high porosity and high specific surface, it has transition phases in a wide temperature range. At higher temperature, due to dehydration and dehydroxylation, the Al2O3surface appears coordination unsaturated oxygen (alkali center) and aluminum (acid center), with catalytic activity. Therefore, alumina can be used as carrier, catalyst and cocatalyst.Gamma activated alumina could be powder, granules, strips or others. We could do as your requirement.γ-Al2O3, was called “ activated alumina”, is a kind of porous high dispersion solid materials, because of its adjustable pore structure, large specific surface area, good adsorption performance, surface with the advantages of acidity and good thermal stability, microporous surface with requisite properties of catalytic action, therefore become the most widely used catalyst, catalyst carrier and chromatography carrier in the chemical and oil industry, and plays an important role in the oil hydrocracking, hydrogenation refining, hydrogenation reforming, dehydrogenation reaction and automobile exhaust purification process.Gamma-Al2O3 is widely used as catalyst carrier because of the adjustability of its pore structure and surface acidity. When γ- Al2O3 is used as a carrier, besides can have the effects to disperse and stabilize active components, also can provide acid alkali active center, synergistic reaction with the catalytic active components. The pore structure and surface properties of catalyst depend on γ-Al2O3 carrier, so high performance carrier would be found for specific catalytic reaction by controlling the properties of gamma alumina carrier.Gamma activated alumina is generally made of its precursor pseudo-boehmite through 400~600℃ high temperature dehydration, so the surface physicochemical properties is largely determined by its precursor pseudo-boehmite, but there are many ways to make pseudo-boehmite, and different sources of pseudo-boehmite leads to the diversity of gamma – Al2O3. However, to those catalysts with special requirements to alumina carrier, only rely on the control of precursor pseudo-boehmite is difficult to achieve, must be taken to prophase preparation and post processing combining approaches to adjust the properties of alumina to meet different requirements. When the temperature is higher than 1000 ℃ in use, alumina occurs following phase transformation: γ→δ→θ→α-Al2O3, among them γ、δ、θ are cubic close packing, the difference only lies in the distribution of aluminum ions in tetrahedral and octahedral, so these phase transformation does not cause much variation of the structures. Oxygen ions in alpha phase are hexagonal close packing, aluminum oxide particles are grave reunion, specific surface area declined considerably.

Storage:lAvoid moisture, avoid scrolling, throw and sharp shocking during transportation, rainproof facilities should be readied..lIt should be stored in dry and ventilated warehouseto prevent contamination or moisture.Package:Type

Plastic bag

Drum

Drum

Super sack/Jumbo bag

Bead

25kg/55lb

25 kg/ 55 lb

150 kg/ 330 lb

750kg/1650lb

900kg/1980lb

1000kg/ 2200 lb

-

Activated spherical shaped alumina gel/High performance alumina ball/alpha alumina ball

Activated Spherical Shaped Alumina gel

for injection in Air dryerBulk density (g/1):690Mesh Size:98% 3-5mm (including 3-4mm 64% and 4-5mm 34%)The regeneration temperature we recommend is between 150 and 200℃Euiqlibrium capacity for water vapour is 21%Test Standard

HG/T3927-2007

Test Item

Standard /SPEC

Test Result

Type

Beads

Beads

Al2O3(%)

≥92

92.1

LOI (%)

≤8.0

7.1

Bulk Density(g / cm3)

≥0.68

0.69

BET(m2/g)

≥380

410

Pore Volume(cm3/g)

≥0.40

0.41

Crush Strength(N/G)

≥130

136

Water adsorption (%)

≥50

53.0

Loss on Attrition(%)

≤0.5

0.1

Qualified Size(%)

≥90

95.0

-

Alpha alumina catalyst support

α-Al2O3 is a porous material, which is often used for supporting catalysts, adsorbents, gas phase separation materials, etc. α-Al2O3 is the most stable phase of all alumina and is usually used to support catalyst active components with a high activity ratio. The pore size of the α-Al2O3 catalyst carrier is much larger than the molecular free path, and the distribution is uniform, so the internal diffusion problem caused by the small pore size in the catalytic reaction system can be better eliminated, and the deep oxidation side reactions can be reduced in the process for the purpose of selective oxidation. For example, the silver catalyst used for ethylene oxidation to ethylene oxide uses α-Al2O3 as the carrier. It is often used in catalytic reactions with high temperature and external diffusion control.

Product Data

Specific Area 4-10 m²/g Pore Volume 0.02-0.05 g/cm³ Shape Spherical, cylindrical, rascated ring, etc Alpha purify ≥99% Na2O3 ≤0.05% SiO2 ≤0.01% Fe2O3 ≤0.01% Production can be customized according to the index requirements -

Sulfur Recovery Catalyst AG-300

LS-300 is a kind of sulfur recovery catalyst with large specific area and high Claus activity. Its performances stand at international advanced level.