Alumina Chemical Filler

-

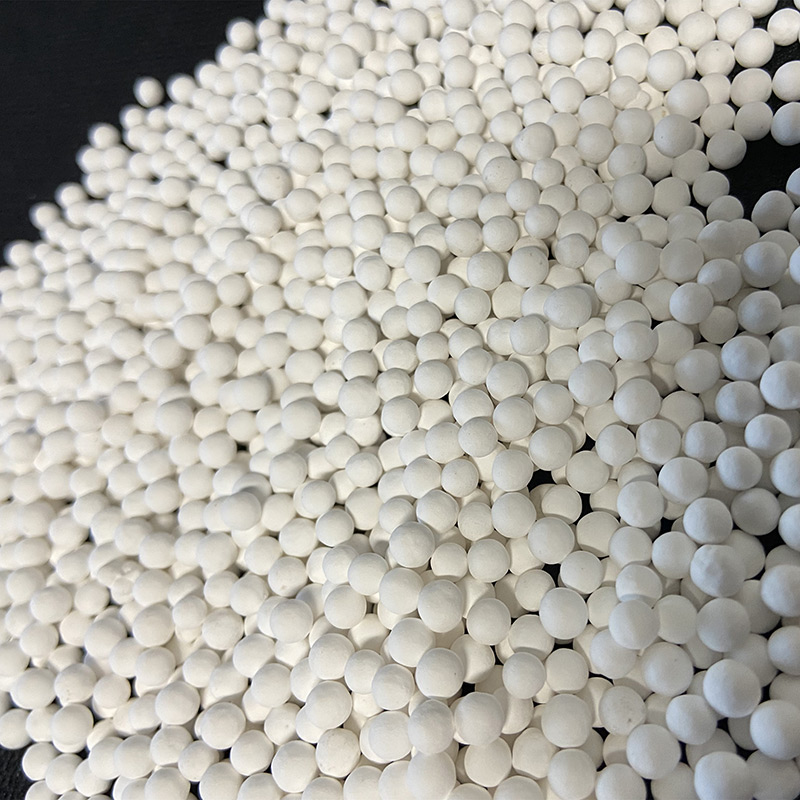

Alumina Ceramic Filler High Alumina Inert Ball/99% alumina ceramic ball

Chemical filler ball properties: alias alumina ceramic ball, filler ball, inert ceramic, support ball, high-purity filler.

Chemical filler ball application: widely used in petrochemical plants, chemical fiber plants, alkyl benzene plants, aromatics plants, ethylene plants, natural gas and other plants, hydrocracking units, refining units, catalytic reforming units, isomerization units, demethylation units Underfill materials such as devices. As a support covering material and tower packing for catalyst, molecular sieve, desiccant, etc. in the reactor. Its main function is to increase the distribution point of gas or liquid to support and protect the active catalyst with low strength.

Features of chemical filler balls: high purity, high strength, high temperature resistance, high pressure resistance, strong acid and alkali corrosion resistance, good thermal shock stability, and stable chemical properties.

Specifications of chemical filler balls: 3mm, 6mm, 8mm, 9mm, 10mm, 13mm, 16mm, 19mm, 25mm, 30mm, 38mm, 50mm, 65mm, 70mm, 75mm, 100mm.

-

Activated Alumina With Potassium Permanganate

It is a chemical adsorption of commonly used materials, new environment-friendly catalyst advanced. It is the use of strong oxidizing potassium permanganate, the harmful gas in the air oxidation decomposition in order to achieve the purpose of purification. The harmful gases sulfur oxides(so2), methyl, acetaldehyde, nitrogen oxides, hydrogen sulfide and low concentrations of aldehydes and org acids have very high removal efficiency. Often used with activated caybon in combination to improve the absorption efficiency. It could be also used in vegetables and fruits as adsorbent of ethylene gas.