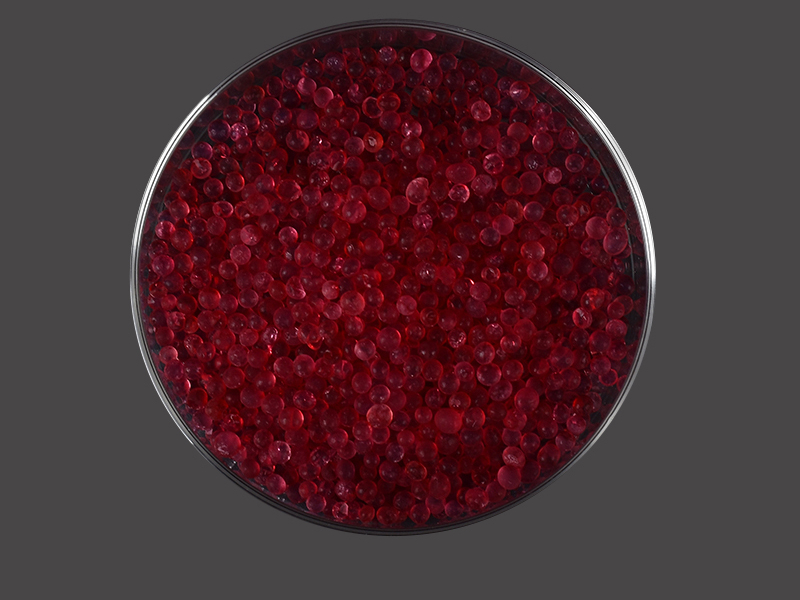

Silica gel is a kind of highly active adsorption material.

It is an amorphous substance and its chemical formula is mSiO2.nH2O. It meets the Chinese chemical standard HG/T2765-2005. It is a desiccant raw material approved by FDA that can be directly in contact with food and drugs. Silica gel has strong hygroscopic ability, strong adsorption performance, even if the silica gel desiccant is fully immersed in water, it will not soften or liquify. It has the characteristics of non-toxic, tasteless, non-corrosive and non-polluting, so it can be in direct contact with any item. The raw materials that need to be prepared for the production of silica gel are: sodium silicate (paucine, water glass), sulfuric acid.

First, the alkali and acid are prepared in advance, and then the solid sodium silicate is melted at high temperature and filtered to prepare a certain concentration of liquid, and then the sulfuric acid is prepared to a certain concentration of liquid, the concentration of sulfuric acid is 20%.

Second, the second step is to make glue (gel granulation), this step is the most critical, the pre-modulated bubble lye and sulfuric acid solution under specific conditions, so as to form a soluble gel solution, after reaching the appropriate concentration will become gel particles. The shape and size of the particles can be completely determined according to the user’s needs and production capacity. The common method of gel granulation is air granulation, and the acid-base ratio, concentration, temperature and gel granulation time used in the gel granulation process are the specific technological parameters.

Third, aging gel needs to go through a certain amount of time and temperature, as well as PH value to age, making the gel skeleton strong, the glue condensation between the particles during the aging process to form Si-O-Si bonds, enhance the strength of the skeleton, the particles are close to each other, reduce the space in the grid structure, and the water contained in it is squeezed out.

Pickling, washing, washing glue Pickling, washing, washing glue is also a very important step in the process, because the Na2SO4 formed by the granular gel is washed away. Control each anion within the range required by the process. It can be said that a large part of the pore characteristics of the finished silica gel is determined by the aging of the rubber washing process, and the aging degree of this process depends on the operation in the pickling, washing, and rubber washing process.

Fifth, drying, the prepared hydrogel (after washing) into the drying room, in specific conditions to reduce the water content of the gel itself drying to the required range. The higher the drying temperature, the higher the rate of primary particle aggregation and the larger the aperture.

Six, screening, the ball selection machine will be dried after the silicone through the screen of different apertures in accordance with a certain particle size screening out, and at the same time will be broken silica gel screening out.

Seven, picking glue: the silica gel in the heterochromatic ball, impurities pick out and then use composite paper according to the requirements of the packaging, after sealing. After the above steps, the silicone product is produced.

Seven, picking glue: the silica gel in the heterochromatic ball, impurities pick out and then use composite paper according to the requirements of the packaging, after sealing. After the above steps, the silicone product is produced.

Post time: Nov-14-2023