Regeneration method of activated alumina

Regeneration method of activated alumina,

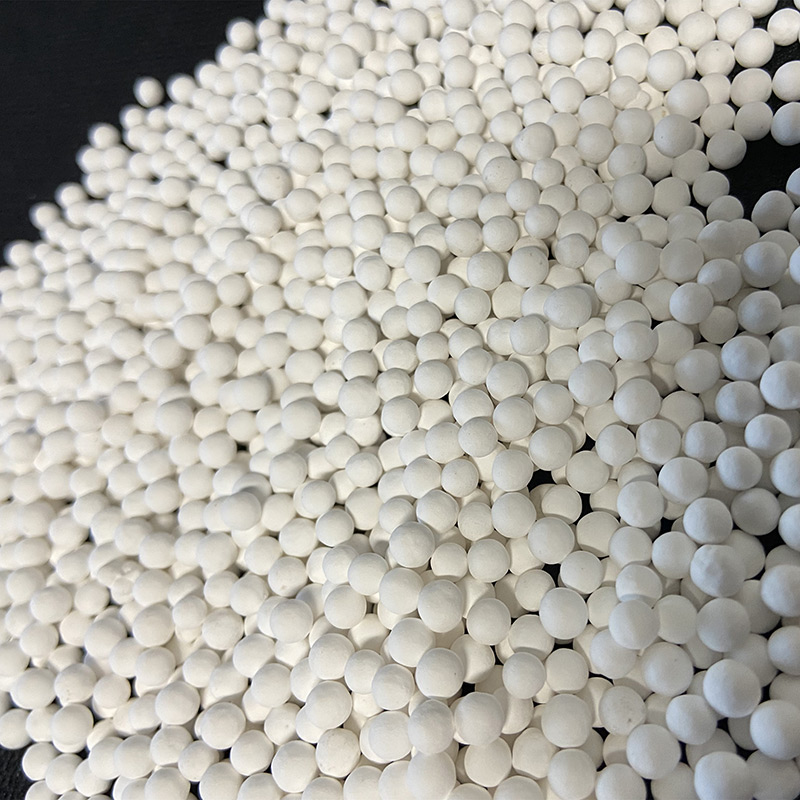

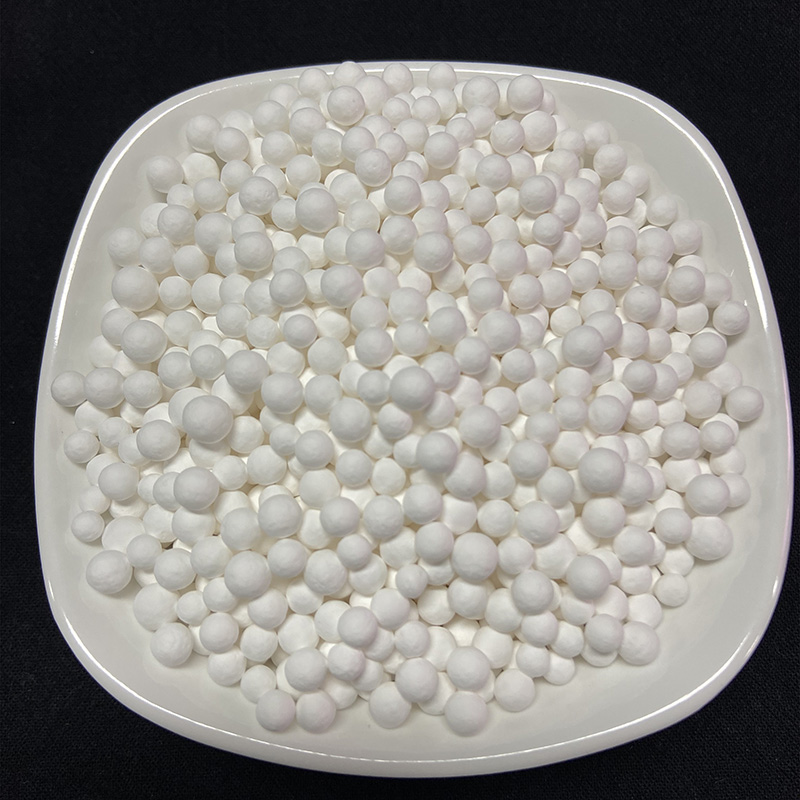

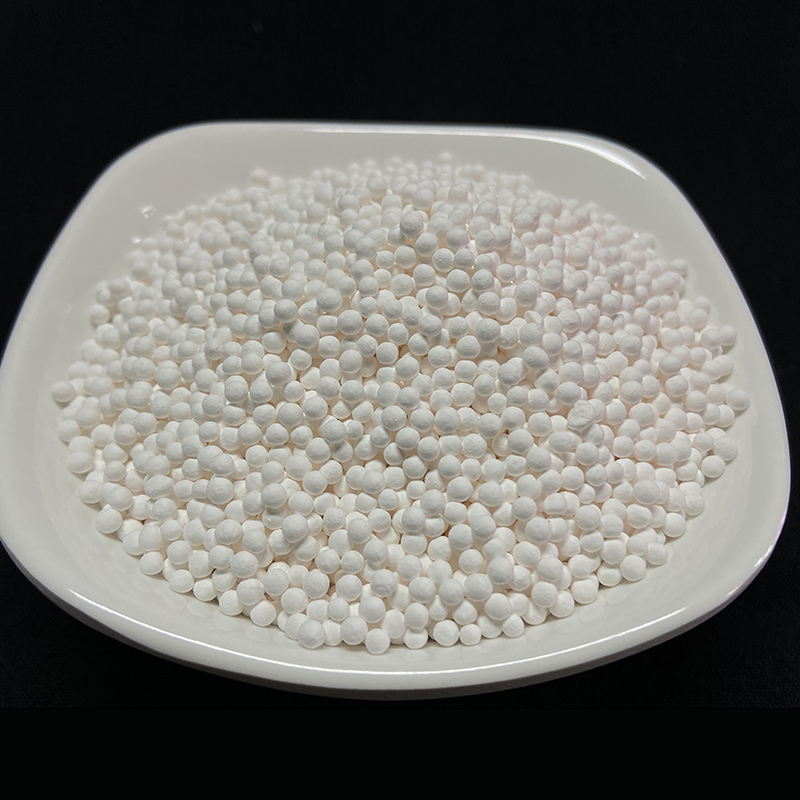

Activated Alumina,

Technical Data

|

Item |

Unit |

Technical specification |

|||

|

Particle siza |

mm |

1-3 |

3-5 |

4-6 |

5-8 |

|

AL2O3 |

% |

≥93 |

≥93 |

≥93 |

≥93 |

|

SiO2 |

% |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

|

Fe2O3 |

% |

≤0.04 |

≤0.04 |

≤0.04 |

≤0.04 |

|

Na2O |

% |

≤0.5 |

≤0.5 |

≤0.5 |

≤0.5 |

|

loss on ignition |

% |

≤8.0 |

≤8.0 |

≤8.0 |

≤8.0 |

|

Bulk density |

g/ml |

0.68-0.75 |

0.68-0.75 |

0.68-0.75 |

0.68-0.75 |

|

Surface area |

m²/g |

≥300 |

≥300 |

≥300 |

≥300 |

|

Pore volume |

ml/g |

≥0.40 |

≥0.40 |

≥0.40 |

≥0.40 |

|

Static adsorption capacity |

% |

≥18 |

≥18 |

≥18 |

≥18 |

|

Water absorption |

% |

≥50 |

≥50 |

≥50 |

≥50 |

|

Crushing strength |

N/particel |

≥60 |

≥150 |

≥180 |

≥200 |

Application/Packing

This product is used for deep drying of gas or liquid phase of petrochemicals and drying of instruments.

25kg woven bag/25kg paper board drum/200L iron drum or per customer’s request.

The Structural Properties Of Activated Alumina

Activated alumina has the characteristics of large adsorption capacity, large specific surface area, high strength, and good thermal stability. substance. It has a strong affinity, is a non-toxic, non-corrosive effective desiccant, and its static capacity is high. It is used as adsorbent, desiccant, catalyst and carrier in many reaction processes such as petroleum, chemical fertilizer and chemical industry.

Activated alumina is one of the most widely used inorganic chemical products in the world. The properties of activated alumina are described below: Activated alumina has good stability and is suitable as a desiccant, a catalyst carrier, a fluorine removal agent, a pressure swing adsorbent, a special regeneration agent for hydrogen peroxide, etc. Activated alumina is widely used as catalyst and catalyst carrier.

Activated alumina is used as a desiccant, mainly used in industrial air pressure drying equipment, air pressure drying equipment has a working pressure, generally below 0.8Mpa, which requires the activated alumina ratio to have a good mechanical strength, if the mechanical strength is too low, it is easy to powder, powder and water combination will directly block the equipment pipeline, so, An important indicator of activated alumina used as a desiccant is strength, air pressure drying equipment, generally two tanks, two tanks work alternately, is actually a adsorption saturation → analytic cycle process, desiccant is mainly adsorption water, but under realistic working conditions, air pressure drying equipment source air will have oil, rust and other impurities, These factors will directly affect the service life of activated alumina adsorbent, because activated alumina is porous adsorption material, natural adsorption polarity of water, oil adsorption is also very good, but oil will directly plug activated alumina adsorption pore, so that the loss of adsorption characteristics, there is rust, rust in water, attached to the surface of activated alumina, Will make activated alumina directly lose activity, so in activated alumina as desiccant use, try to avoid contact with oil, rust, activated alumina adsorbent as desiccant general use life of 1~3 years, the actual use will be to dry gas dew point to decide whether to replace activated alumina. The regeneration temperature of activated alumina is between 180 ~ 350℃. Generally, the activated alumina tower temperature rises to 280℃ for 4 hours. Activated alumina is used as water treatment agent, and aluminum sulfate solution is used as regenerator. The solution concentration of aluminum sulfate regenerator is 2 ~ 3%, the activated alumina after adsorption saturation is placed in aluminum sulfate solution soaking, discard the solution, wash with clean water 3 ~ 5 times. After long-term use, the activated alumina surface is yellowish brown and the defluorination effect is reduced, which is caused by the adsorption of impurities. It can be treated with 3% hydrochloric acid for 1 time and then regenerated by the above method.