Carbon Molecular Sieve

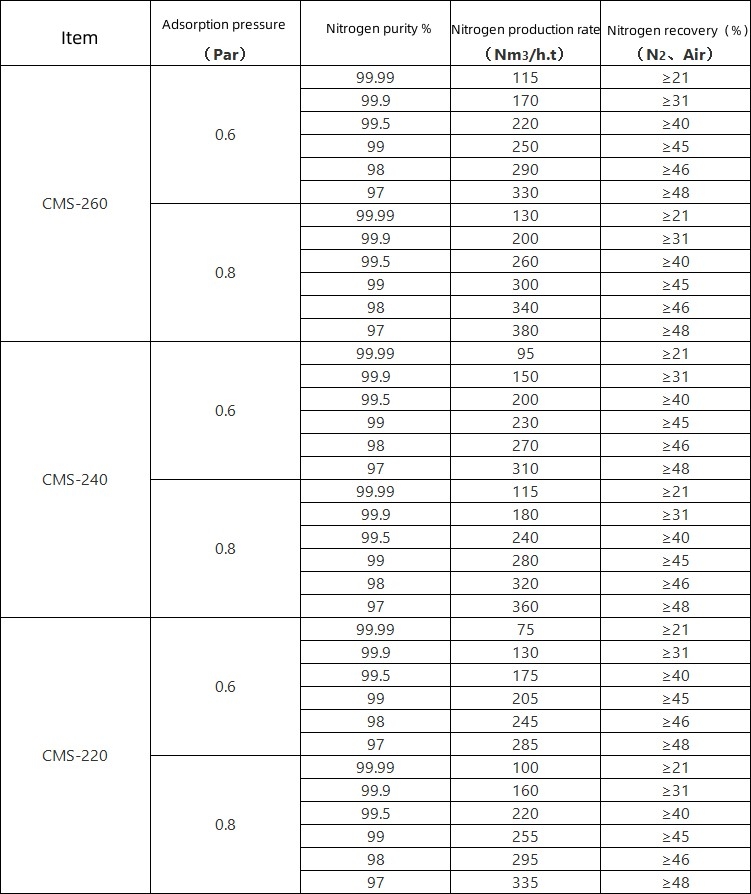

Technical Parameters

1. particle diameter: 1.0-1.3mm

2. Bulk density: 640-680KG/m³

3. Adsorption period: 2x60S

4.compressive strength: ≥70N/ piece

Purpose: Carbon Molecular sieve is a new adsorbent developed in the 1970s, is an excellent non-polar carbon material, Carbon Molecular Sieves (CMS) used to separate air enrichment nitrogen, using room temperature low pressure nitrogen process, than the traditional deep cold high pressure nitrogen process has less investment costs, High nitrogen production speed and low nitrogen cost. Therefore, it is the engineering industry's preferred pressure swing adsorption (P.S.A) air separation nitrogen rich adsorbent, this nitrogen is widely used in chemical industry, oil and gas industry, electronics industry, food industry, coal industry, pharmaceutical industry, cable industry, metal heat treatment, transportation and storage and other aspects.

Working principle: Carbon molecular sieve is the use of screening characteristics to achieve the separation of oxygen and nitrogen. In molecular sieve adsorption of impurity gas, large and mesoporous only play the role of the channel, will be adsorbed molecules transported to micropores and submicropores, micropores and submicropores is the true volume of adsorption. As shown in the previous figure, the carbon molecular sieve contains a large number of micropores, which allow molecules with small kinetic size to rapidly diffuse into the pores, while limiting the entry of large diameter molecules. Due to the difference in the relative diffusion rate of gas molecules of different sizes, the components of the gas mixture can be separated effectively. Therefore, the distribution of micropores in the carbon molecular sieve should range from 0.28 nm to 0.38nm according to the size of the molecule. Within the micropore size range, oxygen can quickly diffuse into the pore through the pore orifice, but nitrogen is difficult to pass through the pore orifice, so as to achieve the separation of oxygen and nitrogen. Micropore pore size is the basis of carbon molecular sieve separation of oxygen and nitrogen, if the pore size is too large, oxygen and nitrogen are easy to enter the molecular sieve micropore, also can not play the role of separation; The pore size is too small, oxygen, nitrogen can not enter the micropore, also can not play the role of separation.

Carbon molecular sieve air separation nitrogen device: the device is generally known as the nitrogen machine. The technological process is pressure swing adsorption method (P.S.A method for short) at normal temperature. Pressure swing adsorption is a process of adsorption and separation without heat source. The adsorption capacity of carbon molecular sieve to adsorbed components (mainly oxygen molecules) is adsorbed during pressurization and gas production due to the above principle, and desorption during depressurization and exhaust, so as to regenerate carbon molecular sieve. At the same time, nitrogen enriched in the bed gas phase passes through the bed to become the product gas, and each step is a cyclic operation. The cyclic operation of PSA process includes: pressure charging and gas production; Uniform pressure; Step-down, exhaust; Then pressure, gas production; Several working stages, forming a cyclic operation process. According to the different regeneration methods of the process, it can be divided into vacuum regeneration process and atmospheric regeneration process. P.S.A nitrogen making machine equipment according to the needs of users can include air compression purification system, pressure swing adsorption system, valve program control system (vacuum regeneration also needs to have a vacuum pump), and nitrogen supply system.